Fortum looks to VR to provide cost-effective training for its operators.

VR is quickly becoming the go-to training solution for a growing number of industries. So far we’ve seen the technology used to enhance medical training, educate employees on critical soft-skills, even prepare store associates for major holiday shopping events. Just recently, Walmart employees credited their VR training as having helped them stay alive during the horrendous El Paso shooting that took place earlier this month.

When it comes to training for dangerous situations, VR allows you to learn and fail without the fear of real-world consequences. This is why Fortum, one of the largest nuclear power generation companies in the Nordics, has begun using VR technology at its Lovissa production site as a way to train employees in how to handle a variety of potentially deadly situations that could happen within the control room.

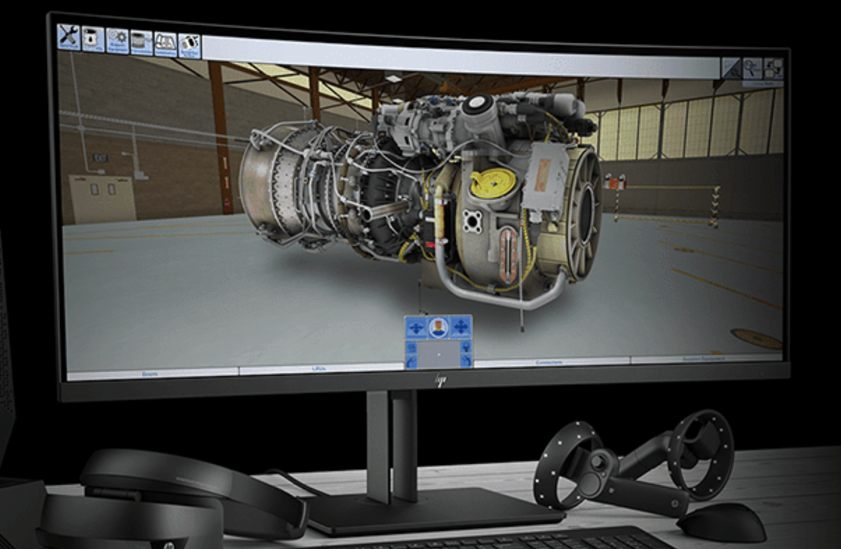

The VR training program uses a Varjo VR-1 headset to deliver immersive training to power plant employees scenarios that range from basic day-to-day work routines, such as monitoring displays, to full-blown life-threatening emergencies.

Program Lead Joakim Bergroth, an expert in human factor engineering with 10 years of experience in the nuclear power industry who leads the program for Fortum, told TechHQ, “In safety-critical environments and process industries, human errors can lead to serious accidents and production losses.”

When it came to choosing a VR headset, Bergroth said the Varjo VR-1 was able to deliver an experience that he’s never been able to get with any other off-the-shelf VR headset, saying, “I was actually able to read manuals and distinguish the smallest digits from a control room display during a VR simulation.”

This level of detail is made possible thanks to Varjo’s use of foveated rendering, a technique that reduces rendering workload by tracking the user’s eyes and decreasing the visual quality of everything in their peripheral vision.

Obviously, when it comes to nuclear power plants, work precision is critical. The slightest error could be costly, with the potential to impact millions of people; therefore the training needs to be just as precise.

A big benefit of VR training is that it is cost-effective for the company. Training in VR is less expensive than training in a physical room because you can get more employees through the training faster. “Physical simulators are usually fully booked, which doesn’t leave much time for additional testing or evaluations,” said Bergroth. Data shows that employees retain more information through VR training in less time, which opens up opportunities for follow up discussions and enhanced training.

Fortum’s VR training room is located at its site in Loviisa, Finland, where 90 percent of the employees have already completed the training. VR training will soon launch at other control room locations for other employees.

Quelle:

Featured Image Credit: Sky UK Ltd ©, HBO

https://vrscout.com/news/nuclear-power-plant-vr-training/