In the industry, change is a constant companion – and with digitization, it is becoming ever faster. The traditional workplace is changing, because digitization is a strategic and technological change in industry that introduces a new era. Our communication, task management and cooperation are fundamentally changed by the large amounts of information and the way they are presented.

As new technologies evolve, ways of working are being re-developed from scratch. Augmented Reality (AR) and Mixed Reality (MR) in particular have the potential to make work in today’s and future worlds more efficient and secure by showing information when and where it’s really needed. In addition to many other areas that benefit from the application of augmented reality, the industry is the industrial sector that benefits the most. Processes of quality assurance, assembly, maintenance and repair, as well as training on complex topics can be improved enormously. The great increase of AR technologies shows just how valuable the implementation can be. In a study by the Munich University of Applied Sciences on the use of augmented reality in the manufacturing industry, 76% of the respondents stated they would like to supplement at least half of their training with augmented Reality applications in the future.

The manufacturer of energy systems VIESSMANN has also recognized the value of new technologies in the course of digitization. In its Smart Factory department, the family-owned company, with around 12,000 employees, works on process suitability of different applications in its production plants. For example, the maintenance and servicing of complex machines can be simplified by using AR. The presentation of important information and instructions as well as the visualization of the work steps as holograms make working with the systems more efficient in the long run. Together with VISCOPIC, the Smart Factory department is testing the use of the Startup’s software products in selected departments. Here, an important requirement is that an open and agile approach is lived within the collaboration. This is realized by the software product PINS from VISCOPIC.

VISCOPIC Pins – Create Augmented Reality yourself

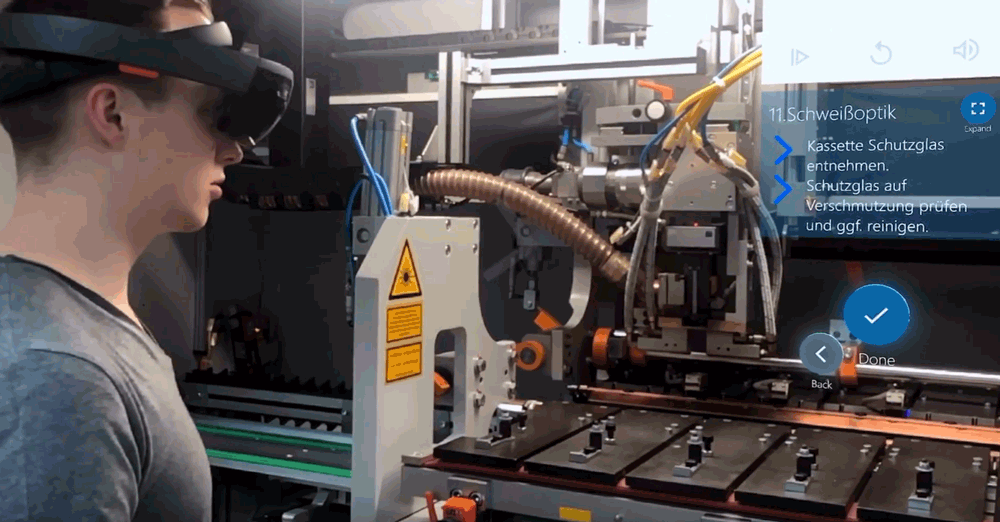

The VISCOPIC Pins application enables the creation and design of AR work steps for various end devices – without programming knowledge. Using data glasses or mobile devices, the generated work and guidance steps can then be projected onto real objects. This simplifies work processes in a wide range of areas by enriching objects and infrastructures with information.

Using CAD data, the program generates a virtual 3D image of an environment or product. This can then be provided with so-called pins. Work steps or checklists, enriched with images, videos, sound or 3D animations, form the attached information units.

With the help of VISCOPIC Pins, workflows can be simplified by displaying important information as holograms at the points that need maintenance on the machine and are available for the technician on various smart devices. In the future, AR could contribute to more efficient and flawless work. In addition, the use of AR creates an exciting experience for the employees who can experience first-hand how digitization supports production.

Another important factor for VIESSMANN is that the use cases can be set up by the employees themselves. Thanks to the software tool from VISCOPIC, workflows can be created by anyone without any programming knowledge. Simply by placing pins on the virtual object, content is positioned and edited. The workflow, which is visualized on the real object using for example the Microsoft HoloLens, can be created with just a few clicks and via drag and drop. This implementation by the PINS Editor is the key to a flexible use of the technology, which can be used regardless of the application, business area or location.

The goal of the collaboration is to make processes in production more efficient and thus to keep pushing digitization forward. The added value for the manufacturer of energy systems is quite clear here: complex work contents can be visualized in a simplified way, which reduces errors, increases quality and shortens learning processes. Digitization is a big issue for the traditional family business in its 102nd year of existence – and it is used as an opportunity to streamline processes, increase efficiency and overcome spatial distances.

Quelle:

https://www.viscopic.com/en/viessmann-smart-factory-with-viscopic-pins/