The Industrial Internet of Things (IIoT) is quickly moving out of incubation zones and into production as it rejuvenates products and operations, while augmented reality (AR) is emerging as the human-centric digital interface into physical environments. While these technologies are on their own respective maturity lifecycles, the future lucrative opportunity to merge IIoT and AR will truly combine the physical and digital worlds.

A PTC and Boston Consulting Group (BCG) collaboration presents new research that supports the idea that IoT and AR are complementary. The whitepaper reports over 80% of IoT current adopters are planning to evaluate AR possibilities and 76% of AR implementors agree there is additional value in adding IoT to their use case.

We’ve distilled adoption trends from PTC’s State of Industrial Innovation report series with BCG & PTC’s ‘Unlocking the Power of IoT with AR’ report to illustrate the industries adopting these technologies right now (the where), the capabilities, use cases, and devices being used (the how), and the business value and ROI being achieved (the why).

The Where: IIoT and AR Find Common Ground in Heavy-Industrial

The consistent performance of products and assets in heavy-industrial operations drives critical daily metrics. Manufacturers are constantly monitoring the uptime of assets along their production lines while end users of industrial equipment such as in utilities are doing the same. IIoT integrates legacy machinery commonplace within these complex industries with industrial connectivity and powerful IIoT platforms democratize this lucrative data for different use cases, roles, and applications.

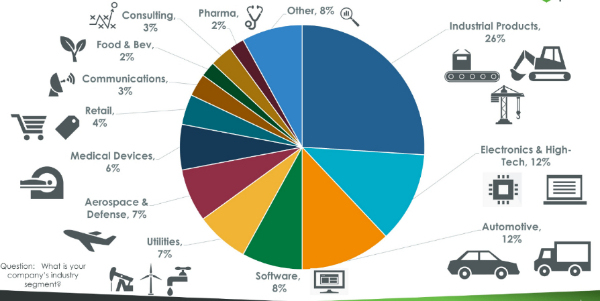

Below is a survey sampling of PTC ThingWorx customers and is not intended to be a full representation of PTC’s IoT customer base.

AR provides a new lens to view this real-time data in-situ for a variety of use cases, which ultimately improve front-line worker productivity. Complimentary to IIoT deployments, AR is also finding a natural fit in industrial arenas; our latest State of Augmented Reality survey data has 20% of AR respondents in industrial products, 9% in Automotive, 7% in Electronics & High-Tech, and 6% in Aerospace & Defense.

The How: Top IoT + AR Capabilities, Use Cases, and Device Adoption

Identifying exactly how and where IoT & AR will impact these verticals and the powerful use cases they’ll enable is an important exercise to developing a business case. BCG & PTC aggregated the anticipated IoT + AR use case adoption from respondents across three capabilities:

- Visualize & Interact (36%): Product design, Consumer navigation, Training

- Diagnose (35%): Equipment monitoring & diagnostics, Buildings/facilities inspection, Insurance claims

- Act (30%): Operator work instructions, Order picking, Heads-up displays

The report also measures adoption of these capabilities across ‘three different areas of value’ in work environments:

- Managing equipment/objects (37%): Construction Design, Product line optimization, Maintenance instructions & guidance

- Managing spaces (27%): Inventory monitoring, Space/Environment monitoring, Spatial optimization (order packing, shipping etc.)

- Enhancing human capabilities (37%): Training (equipment, assembly, use etc.), Remote support, Heads-up displays

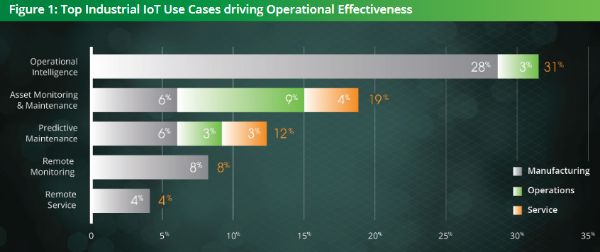

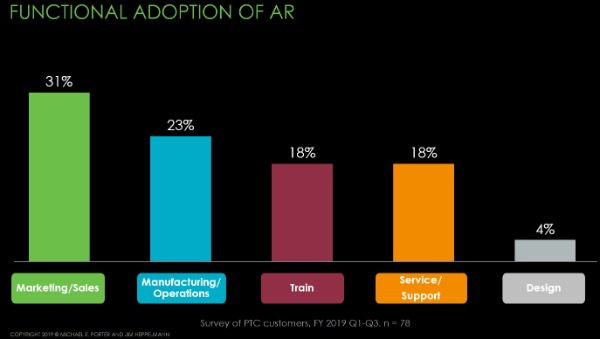

The common themes of these value areas in industrial work environments are also well-aligned to the top use cases (see below) and functions in PTC’s State of IoT & AR reports. The top common functions leveraging IIoT are primarily manufacturing, operations, and service, with AR being inclusive of these three functions as well as training.

The IIoT equivalent for manufacturing to ‘managing spaces’ is operational intelligence where end-to-end visibility of industrial operations and monitoring key efficiency metrics drives crucial KPIs (downtime, overall equipment effectiveness etc.). ‘Managing equipment/objects’ can apply within manufacturing with IIoT use cases for asset monitoring and maintenance and predictive maintenance as well as services use cases for smart connected products including remote monitoring and remote service.

Adding AR into these industrial functions bolsters the workers capabilities, improving productivity and complimentary to IIoT. AR adds a new and immersive HMI to IIoT data such as real-time asset monitoring bringing telemetry data into the operator’s view to maintain uptime. While IIoT in service (remote monitoring) significantly improves technician efficiencies (truck rolls, remote resolutions), field visits still occur, and have implications on downtime and correlating customer satisfaction. AR enables the technician to be increasingly effective in the field and drive critical service KPIs (first-time-fix-rate, time-to-resolution) through augmented procedural guidance or remote assistance. Adding IIoT asset health data to this AR servicing use case adds more context, improving these metrics and the overall service lifecycle.

The two technologies together can both leverage inherent strengths to solve siloed problems as well as come together to improve existing use cases and form new ones.

AR Device Adoption Is Quickly Shifting

The buzz around AR hardware is inescapable as a flurry of product announcements and innovations for headsets continue to gain market-wide attention. Adopters are currently using a mix of smartphones, tablets, and these newer headsets, making it pivotal for AR providers to support the growing range of options.

PTC’s State of Augmented Reality data supports this with the majority of survey respondents leveraging smart phones (80%) and tablets (67%). However, adoption of headsets (47%) is becoming increasingly pervasive with the release of the Microsoft HoloLens2 and other innovations from providers including RealWear, Vuzix, and Magic Leap.

BCG and PTC’s collaboration similarly reports the smartphone (51% of respondents) as the most popular option, followed by HoloLens (39%), Google Glass (18%), Real Wear (11%), and Magic Leap (9%).

The Why: Return on Investment Is Top-of-Mind for Digital Transformation

While cutting-edge technologies like IIoT and AR drive great excitement, tying the technology to encompassing digital transformation strategies with business goals and desired outcomes is critical to success and avoiding proof-of-concept purgatory.

75% of BCG/PTC survey respondents expect ROI of their IoT + AR investments in three years’ time and half who have implemented/or nearly implemented these combined technologies have demonstrated the value internally.

Similarly, PTC State of respondents are quickly moving out of pilots, with 89% of IIoT adopters planning to move to production in under a year and 68% for AR.

Final Thoughts

It is becoming increasingly clear to industrial organizations that the need to change is growing and technology provides the most promising path to do so. IIoT and AR are both demonstrating immense value independently to lighthouse adopters as they rapidly grow out of pilots and into real-world use cases. However, the opportunity to intertwin the two will drive unprecedented value transforming industrial enterprises and creating seamless interoperability between the physical and digital worlds.

Quelle:

https://www.ptc.com/en/product-lifecycle-report/internet-of-things-and-augmented-reality?utm_source=linkedin_free&utm_medium=social_corp&utm_campaign=blog_iotarwherehowwhy